Diamond blade discs have different functions. Asphalt Blade is used to cut asphalt and there are many categories depending on the use. High-performance blades are what we use to cut hard asphalt. We can use medium-performance discs to cut asphalt with less traction. Speaking of diamond saw blades, cutting is not their primary function.

It is used for grinding. These blades can cut steel and aluminum because they contain microscopic diamonds, but they don’t move as fast as a concrete blade. When cutting steel or metal, the diamond fuses into a mold that allows grinding, and when we do, it turns into a fine powder. Although it takes longer than other blades, this blade can cut steel. When cutting steel with a diamond blade, the diamond breaks and the quality of the blade deteriorates rapidly.

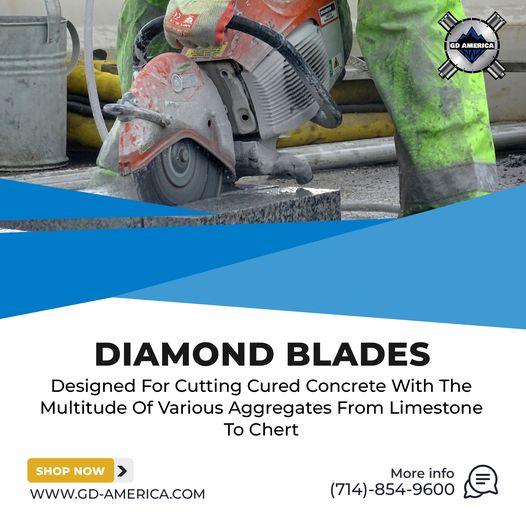

Production of diamond discs

Unlike grinding wheels and concrete grinding wheels, diamond grinding wheels are produced by a separate production technique. Strong metal forms into a flat circle, known as the core of the outer part of the backing disc. The outer layer of the blade is covered with a tiny diamond. Typically, these vanes are U-shaped. Laser welding or vacuum welding is used to join the diamond to the disc. The realization of a solid connection with the diamond depends on the speed of the wheel.

Aluminum cutting

For metal cutting, consumers often look to abrasive or carbide blades. These blades are made with the quality of the metal in mind and their primary function is to cut metals with a strong bond. A diamond blade can also cut steel, although it takes longer and is more expensive. We can examine the results of several tests and compare diamond grinding wheels with other grinding wheels.

There is a difference of seconds when cutting 18 gauge metal with diamonds and grinding wheels. The time difference will be greater if we cut the steel to a greater thickness, such as 8 inches. 8″ steel can be cut in seconds, but due to the strong adhesion of steel, a diamond wheel needs 30 to 40 seconds to complete the job. thick steel. In any case, 1/4″ steel is excellent and will do the job. Diamond will damage and potentially break in 3- 4 minutes that a diamond wheel takes to cut. During this delayed process, frictional heat also increases, reducing the quality of the board.

Cutting abrasive materials

These Asphalt blades can cut steel because each section has a small diamond on it, although not as fast as grinding blades can. The diamond is mounted so that it can be used for grinding, and if we use it to cut metal or steel, it will reduce the material to a fine powder. Cutting steel is doable with this blade, but will take considerably longer than with other blades.

The diamond in a diamond blade will split if we keep cutting steel with it, and the blade will wear out prematurely. We can examine the results using a separate experiment to compare diamond wheels with other grinding wheels. The difference in cutting time when using diamond and metal 18 abrasive wheels is only a few seconds. Using a grinding wheel will take up to 11 or 12 seconds to cut diamond metal. So clearly there is a slight difference. The time required changes slightly if we cut steel that is a bit thicker, say 8 inches. Due to the strong bond between the steel, diamond blades cut 8″ steel in approximately 30 to 40 seconds compared to 18 seconds for abrasive blades.

When cutting quarter-inch steel, we can tell a significant time difference between the two blades. It takes almost a minute to cut 1/4″ steel with a grinding wheel, which is still good and efficient. A diamond wheel can cut it in 3-4 minutes. It can cause them to break and damage the diamond. This laborious operation increases the heat due to friction, which reduces the quality of the blades.

Conclusion

In a word, we can say that each blade fulfills a different role. They will present problems, although they can be used for many activities. Concrete and asphalt wheels are used to cut concrete and asphalt materials such as sidewalks and roads, while diamond wheels are usually used for grinding rather than cutting. If a diamond blade is used for the cutting process, it is a waste. Due to its unique design and manufacture, this blade is only used for grinding. You will misuse it for something else.