Table of Contents

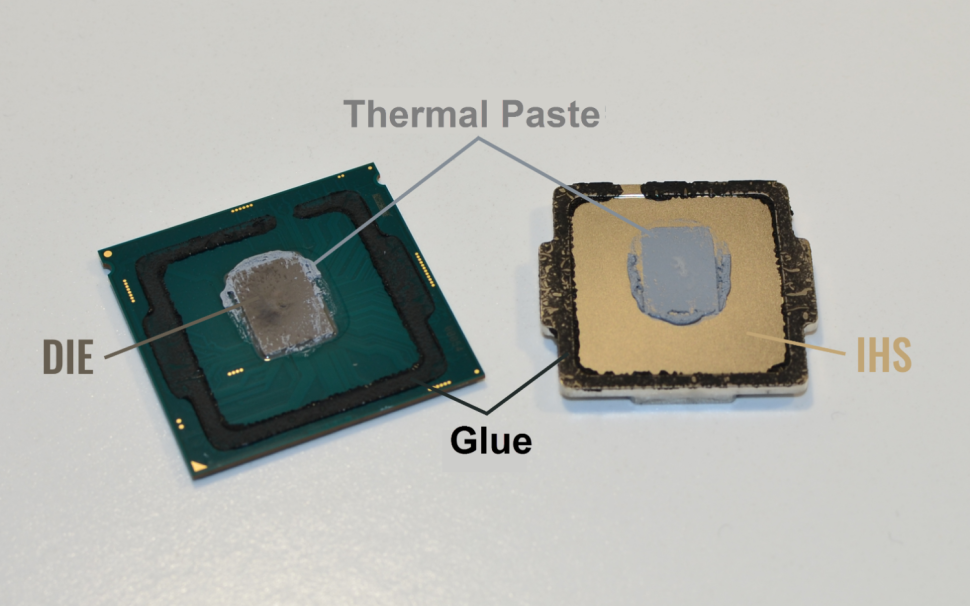

ToggleUnderstanding thermal property testing is the key to developing high-performance materials and products for a wide range of applications. Whether you’re designing new building insulation or a state-of-the-art computer chip heatsink, knowing how your product performs under heat transfer conditions is critical to your success.

For many products, the primary properties of interest are thermal conductivity and specific heat capacity. These two metrics help predict the performance of insulators, phase change materials, heat exchangers, and evaporators.

Thermal Conductivity

When developing high-performance products, thermal conductivity is an important factor. It determines how effectively a material can perform its function.

It is an important property for the development of high-performance systems, as it allows for efficient heat transfer. Also, it also helps to ensure that heat does not cause damage to a product or component by limiting the amount of power dissipation.

Because of its intrinsic nature, thermal conductivity can change based on the type, structure, and state of a material. It is also a function of the material’s temperature, which can be very variable.

Metals are usually highly thermally conductive due to the delocalized electron movement within metallic bonding. This increases the internal particle velocity, which transfers heat with less resistance. The inverse of thermal conductivity is thermal resistivity, which is the degree to which a material acts as an insulator.

In addition to the effect of thickness, temperature has a large influence on the overall magnitude of thermal conductivity. In addition, changes in orientation can also impact the thermal conductivity of a material.

Luckily, there are several methods available that can predict the thermal conductivity of a material without using the traditional continuum-based Fourier equations. For example, ab initio quantum mechanical computations can predict thermal conductivity in terms of fundamental atomic properties without reference to existing measurements. The results are often called “reference correlations,” which can be useful for predicting thermal conductivity at a user-specified temperature and pressure. These reference correlations can be proprietary or open-source, depending on the material being modeled.

Thermal Resistance

Thermal resistance is an important property of any material or system that limits the flow of heat. It can be measured as a number between 0 and 1, with 0 representing no resistance and 1 representing maximum resistance.

A high thermal resistance can cause overheating and circuit malfunctions, which is why it is essential to test thermal properties before developing a product or designing a PCB circuit. This is especially true for electronics, which can be affected by rising temperatures.

The thermal resistance of an IC package is the measure of how well it can transfer heat from the IC to the ambient air, the circuit board, or the heat sink. Knowing this value helps engineers determine which thermal interfaces are best for a given device.

This is why it is important to test and compare the thermal resistance of different packages. For example, if you are comparing two low-voltage regulators with similar ratings and input-output voltage ranges, you can use thermal resistance to distinguish the devices that are most likely to overheat.

Another way to test thermal resistance is by using a thermal simulator that can simulate the steady-state heat transfer of a system. These programs can help users develop accurate package and system thermal predictions.

The simulations can be based on empirical data or on mathematical models. The combination of the two is referred to as “thermal-analysis software.” FLOTHERM(r) and other thermal-analysis programs allow engineers to accurately predict the thermal performance of their packages and systems.

For example, they can calculate the junction-to-air (thJA) and junction-to-case (thJC) thermal resistances for an IC package.

A low thermal resistance also means that it is easier for a material to conduct heat, which is important in the semiconductor industry. Typically, unipolar semiconductor devices are thermally conductive, while bipolar semiconductors are not.

Thermal Insulation

Whether you’re building new insulation for your home or working on heat transfer technology for metal-alloy computer chips, understanding thermal properties is essential.

In addition to thermal conductivity, there are a few other important thermal properties to understand when developing high-performance products and systems. This value is usually the limiting factor when choosing a material for a particular application because a low Specific Heat Capacity can reduce the overall efficiency of the system and lead to higher energy costs.

Another key property to understand is the thermal vapor transmission rate of a material. Vapors can enter a system through leaks, cracks or imperfections in the seals, and the resulting moisture can quickly degrade and damage insulating materials or the equipment that uses them.

Heat Transfer

In the development of high-performance products it is vital to ensure they have the right thermal properties. This includes the ability to conduct and absorb heat and also the capability to withstand temperature changes and the effect of thermal cycling.

Accurate information on the thermal conductivity of a material is crucial for all of these requirements. Element are able to provide effective thermal conductivity testing and measurement services for a wide range of materials, including liquids, ceramics, plastics and polymers, coatings (epoxies, resins and glues), composites and building materials.

A common method to test thermal conductivity is the Transient Plane Source (TPS) technique that uses a hot-disc sensor to apply heat pulses over several seconds and minutes to a sample.

Another important test is the time-domain thermo reflectance test which can measure a material’s thermal properties testing by observing the change in reflectivity of the surface when heated. This is particularly useful for thin film materials, where the heat transfer properties vary considerably.

Air movement can also be a form of heat transfer, either through ‘forced’ air movement (eg from fans or ventilation), or ‘natural’ air movement as a result of pressure differences between different parts of a building.

Using this information it can be possible to design an internal environment which can regulate and stabilize the temperature in a building, as well as minimize the use of energy for heating or cooling.

Thanks for visiting soogam